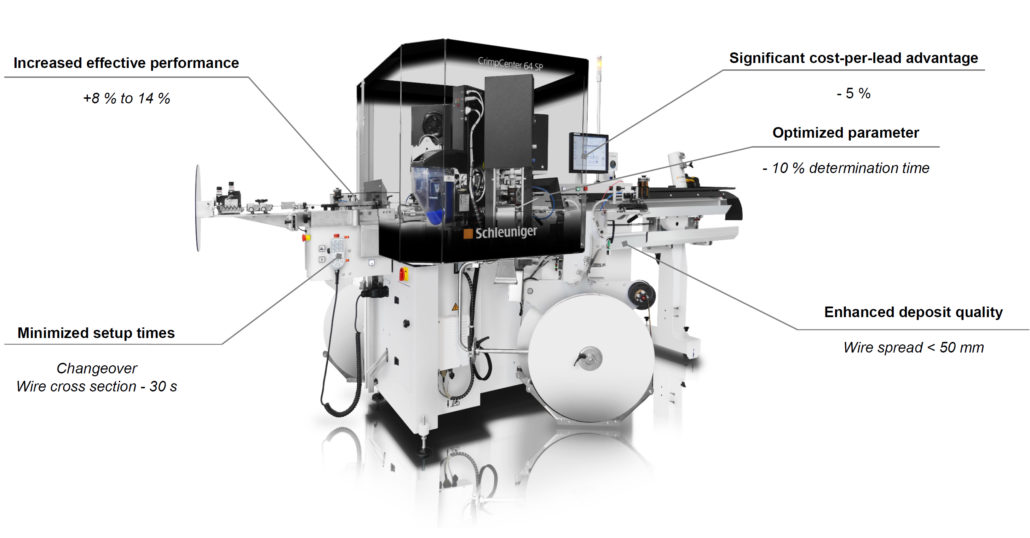

With the CrimpCenter 64 SP you not only produce more precisely, quality consciously and between 8 and 14 percent faster. The latest creation from Schleuniger has also been designed with a focus on achieving your production goals more cost effectively.

The latest creation from Schleuniger has also been designed with a focus on achieving your production goals more cost effectively. The innovative fully automatic crimping machine provides you with a significant cost-per-lead advantage of minus 5 percent compared to its predecessor, remarkably efficient setup times, as well as numerous innovations that have a positive effect on your work process and daily routine.

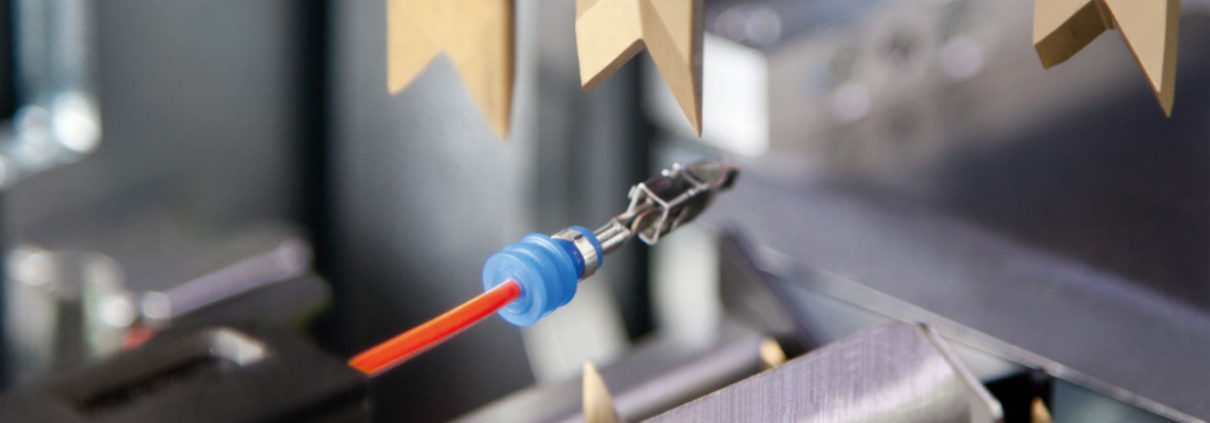

Furthermore, the new CrimpCenter 64 Performance Package offers an extensive list of innovations: Applicationspecific default values for process parameters, automatic control of the pneumatic pressure of conveyor belts and gripper systems, a sophisticated straightening unit and a newly developed roller design for very thin, demanding cables. Add to this a newly developed deposit gripper system that ensures perfectly aligned production batches for easy removal. And with integrated crimp force monitoring for multiple stamped terminals as well as a split-cycle function, it is possible to process belted, preinsulated and even closed-barrel type terminals as standard.

In addition, you can supervise all quality-relevant processes in real time.

CrimpCenter 64

Read more in the Schleuniger press release.